Assemble a forklift using metal parts you bend yourself!

This article introduces a unique factory tour designed for visitors who want to learn about Japan’s world‑class manufacturing culture directly at the production site. The program takes you into a real precision sheet‑metal workshop, where you can observe the advanced skills that support Japanese manufacturing and experience the craftsmanship up close. Beyond simply watching the production process, participants have the rare opportunity to learn directly from skilled craftsmen and try metal‑bendi...

-

Table of Contents

- From a Single Metal Sheet to Precision Parts: Ultra‑Thin Processing at 0.1 mm

- Take a Peek Inside the Tour!

- Factory tour

- Metal‑Bending Experience

- Tour Details

- How to contact us

From a Single Metal Sheet to Precision Parts: Ultra‑Thin Processing at 0.1 mm

There is a company in Osaka, Kawachinagano that has been engaged in precision sheet metal processing and press working for over 50 years.

They manufacture the essential parts inside electronic and industrial equipment, and are like the "unsung heroes" that support our daily lives. They have mastered the "cutting, bending, and assembly" of metal plates, achieving high precision that allows them to freely process even materials as thin as 0.1 mm. Although the process may seem simple, it is the result of experience and technology accumulated over many years.

Take a Peek Inside the Tour!

Here is a look at the tour. The tour flow is as follows:

Factory tour ⇒ Metal bending experience

Factory tour

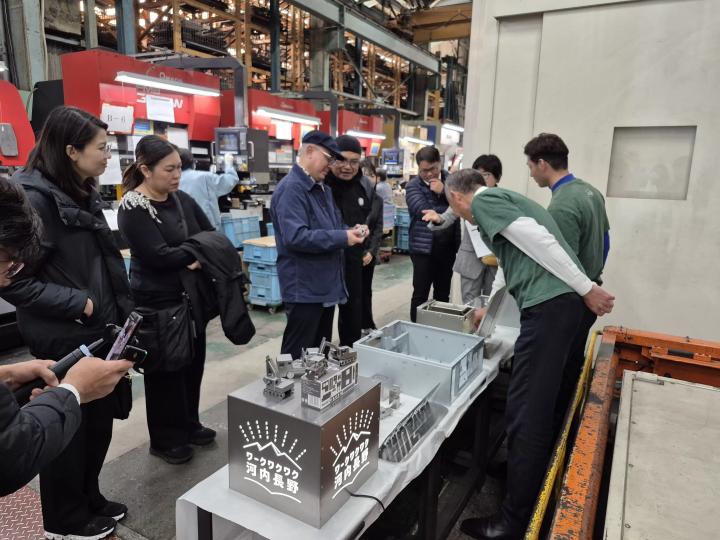

Before stepping inside the factory, the president first spoke to us about the company's history and business activities, including the meaning behind the company name, 5S activities aimed at creating a comfortable working environment, and initiatives to contribute to the local community. Learning about the values and background of a company that has continued to hone its technology while rooted in the local community instantly heightens our expectations for the workplace we will soon see.

After the company introduction, we finally headed inside the factory.

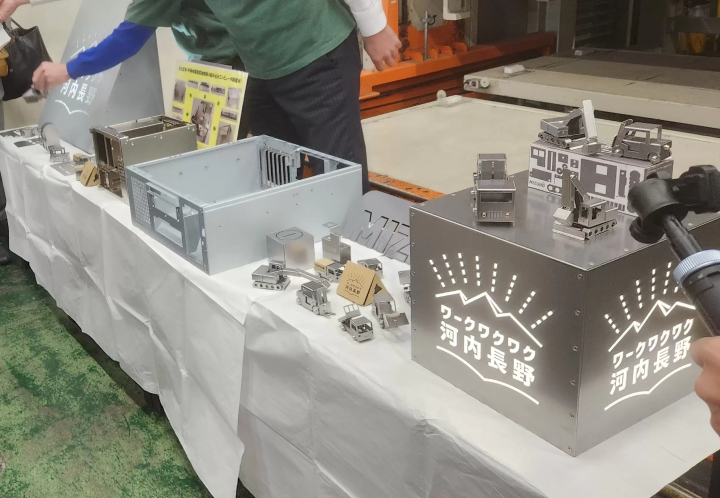

Inside the factory, you can see the actual products being manufactured, including parts for computers and other electronic industrial equipment, as well as miniature cars and piggy banks that were sold at the Osaka-Kansai Expo.

Apparently, they regularly manufacture around 1,000 different parts using precision sheet metal processing. The participants were fascinated by the transformation of a single sheet of metal. Questions flew one after the other, creating a lively atmosphere at the site.

Next, staff will guide you through the actual production line, showing you how a single metal plate is transformed into a finished product.

First, we will introduce "punching," a basic process in precision sheet metal processing. Sheet metal processing begins with organizing the necessary information based on the drawings received from the customer and creating a dedicated program to operate the machine.

First, we will introduce "punching," a basic process in precision sheet metal processing. Sheet metal processing begins with organizing the necessary information based on the drawings received from the customer and creating a dedicated program to operate the machine.

This is the mold that is actually used in the punching process. When you pick it up, you'll be surprised at how much heavier it is than it looks.

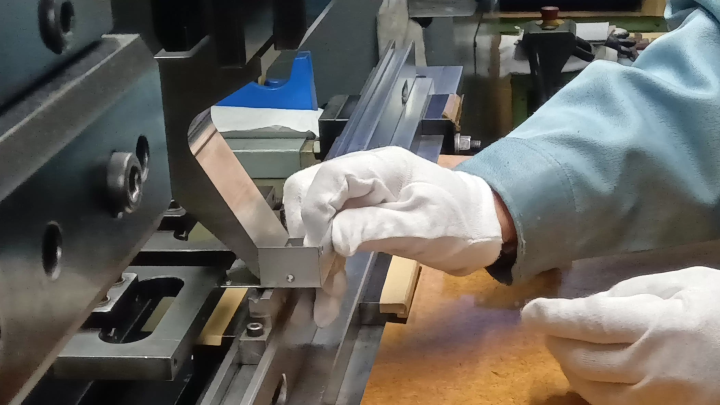

The next step is the bending process, which forms the material into a three-dimensional shape.

In the "bending process," the metal plates cut out during the punching process are precisely bent at angles according to the blueprint to create three-dimensional parts. Even the slightest deviation in angle affects the subsequent assembly process, so high processing precision and the experience of craftsmen are essential.

The processing is carried out with care to ensure that there are no deviations in dimensions or angles, taking into consideration the temperature of the day and changes in the surrounding environment. At the site, you can hear directly from the engineers who work on manufacturing every day about the ingenuity and attention to detail that goes into the processing.

Metal‑Bending Experience

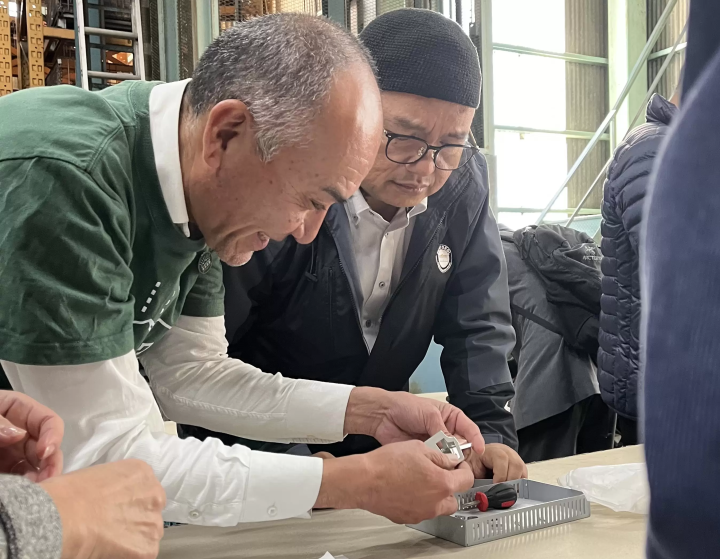

After the factory tour, you will have the opportunity to try out the bending process of metal sheets.

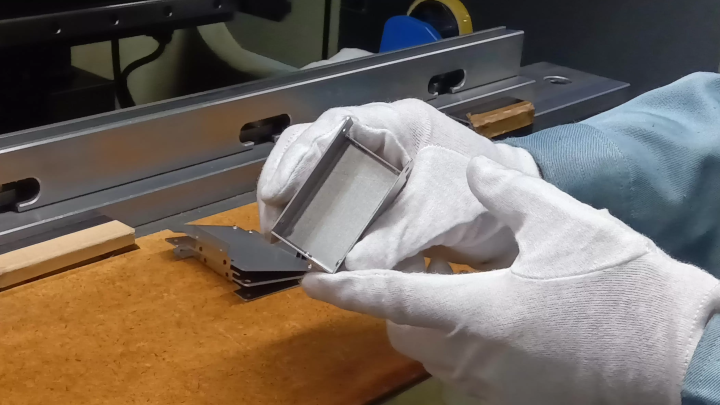

With the support of specialized staff, you can operate the actual machine and see with your own hands how the metal plate gradually transforms into a three-dimensional shape.

The unique feeling of the metal bending every time the machine moves is a first-time experience, allowing you to fully experience the "joy of manufacturing."

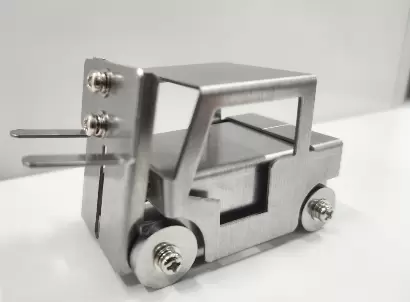

After completing the bending experience, you will have the opportunity to try assembling a miniature forklift car.

You will be able to experience the entire process from processing to assembly, incorporating the metal parts you have just processed with your own hands.

The movement of the tires and lift changes depending on how it is assembled, so it's great to see the connections between each process and the difference in the finished product. Watching the parts you've shaped with your own hands take shape as a miniature car gives you a sense of the depth of craftsmanship and a sense of accomplishment.

You can take home the forklift you made yourself as a souvenir! Experience the fun and difficulty of sheet metal processing through this experience that can be enjoyed by children and adults alike.

Tour Details

During the factory tour, you will get to see up close the "precision sheet metal processing" site, which you would not normally be able to come into contact with. In the metal plate bending experience, you will be able to process the metal with actual machinery and try your hand at making a forklift. This is a valuable experience that allows you to experience the technology of precision sheet metal processing and the joy of manufacturing.

・Price: 2,600 yen (tax included) per person ・Number of people: 4 to 20

・Duration: Approximately 120 minutes ・Contents: Factory tour + metal bending experience

・Application acceptance: up to 2 weeks in advance

As you watch the metal parts you bend yourself become completed parts, you can clearly see the connections between each process and the differences in the finished product, truly experiencing the "fascination of precision sheet metal processing." Don't miss this rare opportunity to experience Japan's advanced technology. Visitors from overseas are also welcome. (*An interpreter must be present.)

How to contact us

1. Please fill out the necessary information in the form below and contact us.

2. We will contact you from "industrial.tourism@nankai.co.jp" within 3 business days.

Please feel free to contact us for any enquiries about available dates or detailed tour information!

[Where tradition meets modernity] We will spread the appeal of Wakayama and Osaka to the world. HP: https://www.japanrootsguide.com/jp Let's travel Japan together and create inspiring stories and unforgettable experiences. From the tranquil temples and shrines of Wakayama and the soothing green mountains to the vibrant city and delicious food of Osaka, We will deliver the charm of this place to you in full detail. Let's join us and enjoy the beauty of Japan. "This account is operated by Nankai Electric Railway Co., Ltd." [Photo description] 1. Rapi:t Express Train Connecting Kansai International Airport and Namba 2. Nachi Falls and the Mie Pagoda of Seiganto-ji Temple (Photo courtesy of the Wakayama Prefecture Tourism Federation)

The contents on this page may partially contain automatic translation.

![[Southern Oita Prefecture (Usuki and Saiki)] A journey through fermentation and tradition. Oita Sustainable Gastronomy](https://resources.matcha-jp.com/resize/720x2000/2026/02/27-259975.webp)

![[Hiroshima] ORIZURU Making at the Hotel / Sheraton Grand Hiroshima Hotel](https://resources.matcha-jp.com/resize/720x2000/2026/02/26-259811.webp)

![[Aichi] 30 minutes from Nagoya! 8 must-see tourist spots in Tokoname, the city of beckoning cats and pottery](https://resources.matcha-jp.com/resize/720x2000/2026/02/26-259808.webp)