"CRAFT TOURISM ECHIZEN" Echizen Kama, the only one in Japan that inherits the skill

Many people think of forged kitchen knives when they hear the traditional handicraft of Echizen City, “Echizen Uchihamono”. However, what was actually made before kitchen knives was a sickle for agricultural work called "Echizen sickle".

Echizen Sickle

The sickle may not be very familiar nowadays, but it is actually one of the tools that is useful in a wide range of situations, such as weeding, rice harvesting, and home gardening.

Let's talk about Echizen's sickle, which is indispensable for such farm work.

sickle merchant

Echizen sickles made with the skills of a swordsmith

Production of Echizen sickles began in the Kamakura period. Kuniyasu Chiyozuru, a swordsmith from Kyoto, stayed in Echizen in search of water to forge his famous swords, and began to make sickles as well as swords.

In the Edo period, each feudal lord strengthened the protection and development of agriculture and forestry, and the total area of fields expanded. As a result, agricultural implements began to be mass-produced, and Echizen sickles began to be exported to various places.

Kamayuki merchants played an important role in its spread.

Lacquerer

Penetration throughout the country by lacquer scraping

Echizen sickles were sold by merchants who lived in Fuchu Takefu, which is now Echizen City. Many of the Kamayuki merchants were originally lacquer shaving craftsmen who collected the sap that flows out of the lacquerware. He was working as a lacquer worker in various places.

When a lacquer worker went out to work, he always brought an Echizen sickle. It boasts outstanding sharpness and robustness due to the advanced technology cultivated in the production of swordsmiths. Lacquer craftsmen use this sickle for their work, and when the work of lacquer scraping is off due to rain, they sell the Echizen sickle they brought to the people of the nearby mountain villages, and order sickles according to the local characteristics. brought back the

In the Meiji period, cheaper Chinese lacquer was imported, and Japanese lacquer stopped selling. Although the production of sickles also decreased, the production area of Echizen cutlery remained stable until the early Showa period, with most of the production of sickles in Japan being produced in Echizen.

Kato Cutlery Factory

Echizen sickles that continue to be made using traditional manufacturing methods

After the war, with the rapid economic growth, the mechanization of agriculture progressed rapidly, and the production of Echizen cutlery shifted from sickles to knives and knives.

Nowadays, the number of workshops that make Echizen sickles has completely decreased, but there is one in Echizen City that still continues to make them using techniques that have been used since ancient times.

It is “Kato Takefu Knife Village and Echizen City.

For three generations, they have been producing knives by forging, but among other things, the manufacturing method for saw sickles, which are used for agricultural work such as rice harvesting, can only be found at Kato Uchihamono Seisakusho in all of Japan. It is a special technique that has not been inherited.

As the name suggests, the saw sickle is characterized by its serrated blade. Many sickles made overseas are cut out of steel by machine, but at Kato Uchihamono Seisakusho, the eyes are added manually one by one using a method called "mekiri."

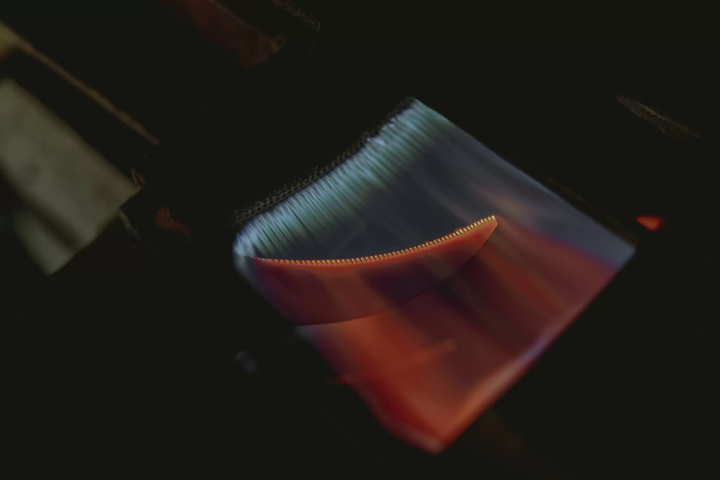

▲ Press the steel into the grooves of the machine and mark the eyes

Then, sharpening the jagged eyes is "setting". The work of carefully polishing each eye with a file is meticulous and takes a lot of time and effort.

▲The sound of sharpening with a file reverberates through the studio.

The sickle that has been sharpened is heated to a high temperature of around 800 degrees Celsius, and then quickly cooled with water to make it hard. Scythes made through this process are strong despite their thin blades.

Saws and sickles are usually replaced every year. It is said that if you use it hard every day, such as when harvesting rice, the blades of some blades will wear out before the end of the harvest season, but Kato Uchihamono Seisakusho's saw sickles remain sharp until the end of the year's harvest. never abates.

“If you sharpen your eyes by hand, the length of the eyes will be slightly different, such as those with long or short peaks. That's why it keeps its sharpness for a long time."

Mr. Kato, who continues to make Echizen sickles at Kato Uchihamono Seisakusho, told me.

▲Mr. Kato has been making Echizen sickles for over 20 years. The charm point is the gentle smile that is far from the image of a stubborn craftsman.

The benefits of hand-made knives are not limited to sharpness. It is also possible to make a special sickle that suits the purpose of the person who uses it.

In addition to rice harvesting sickles, there are various types of sickles, such as the weeding sickle, which has a particular angle to enter the soil when weeding, and the asparagus sickle, whose handle length tells you when to harvest. However, the "rakkyo sickle" and "left-handed sickle", which have the edge of the blade facing the opposite direction, can only be made by hand cutting.

“Sometimes I wonder why I keep going through such a difficult task (laughs).

No matter how much mechanization progresses, sickles are still useful in small fields and home gardens where agricultural machinery cannot enter. There are many people who say that once they use it, they can't let go of the ease of use, such as the good balance that fits in the hand and the sharpness that allows you to harvest without stress.

The Echizen sickle, which has been lovingly sharpened using techniques that have been handed down over many years, will continue to play an active role in fields all over the country as a reliable partner for farmers.

▼Kato Cutlery Factory

Echizen wisdom ~Proposing a new tourism, a journey of wisdom.~ A town that has inherited the skills and spirit of its predecessors for 1,500 years. Echizen, the entrance to the "Koshi no Kuni" ruled by an ancient king. A place of wisdom where cutting-edge technology and culture first flowed in from across the Sea of Japan and became the origin of Japan's profound manufacturing. In the traditional industries that coexist with the nature of the land and in the people who live here, the universal wisdom that human beings want to bring to the next 1000 years is alive. Here and now, there is a future born from exchanges that transcend national borders and time and space. A new quest to find light. Welcome to Echizen.

The contents on this page may partially contain automatic translation.

![[2025 Edition] Best Places to See Cherry Blossoms in Fukui, Japan – Top 10 Spots for Hanami & Stunning Views](https://resources.matcha-jp.com/resize/720x2000/2023/03/09-135755.webp)

![[Shinjuku Nishiguchi HALC] About the d Point Campaign](https://resources.matcha-jp.com/resize/720x2000/2026/02/14-258714.webp)