Witness The Making Of A Sword! The Bizen Osafune Japanese Sword Museum

The art of Japanese sword making lives and breathes in Okayama prefecture's Setouchi city. Artisans today carry on a tradition spanning centuries and offer visitors a uniquely enriching and intimate view of this fascinating and beautiful art.

The Japanese sword making tradition has a history that stretches over a millennium. Born out of necessity, swords have been forged by swordsmiths over the centuries and wielded by warriors on the battlefield.

The art of sword making has also developed over the centuries, and has been shaped as much by the demands of battle as by aesthetic considerations. This in turn demands both technical and stylistic artistry, and is what lies at the heart of Japanese sword making.

The Bizen Osafune Japanese Sword Museum in Setouchi, Okayama Prefecture, is a facility where visitors can witness all the stages of making a Japanese sword and even take part in workshops that facilitate a deeper understanding of the art.

The Japanese Sword

Photo courtesy of Bizen Osafune Japanese Sword Museum

In Japanese history, the changes in fighting styles on the battlefield were often reflected by changes in the type of weapon used.

Perhaps the most commonly known sword is the katana. The katana rose to ascension during the Edo period (1603-1868), when it's thought that the beauty and quality of the Japanese sword was at its peak. It was wielded by the samurai, members of the ruling warrior class, and often paired with a shorter sword called wakizashi.

Bizen Osafune Japanese Sword Museum in Setouchi City, Okayama Prefecture

Setouchi City in Okayama Prefecture has one of the longest traditions of making Japanese swords. The city is situated upon the Seto Inland Sea to the south and was historically a major port of trade. Importantly, the Chugoku mountains to the north hold a wealth of iron sand which is the raw material for forging steel for the blade.

Today the tradition of Japanese sword making in Setouchi continues, and visitors to the Bizen Osafune Japanese Sword Museum will have the unique opportunity to observe for themselves the process of forging a blade by traditional methods.

A series of ateliers, artisan studios, surround a courtyard on the grounds of the Bizen Osafune Token Village. There are eight separate ateliers including the forge. In each of them, the different parts of the sword are fashioned. A period of several months is required to bring a sword from the swordsmith's forge to the final polishing and engraving stage.

The layout of the Bizen Osafune Token Village reflects the sequence of steps in making a sword. Visitors are welcome to walk about and step inside each of the separate ateliers. The artisans work within the ateliers themselves, and, in the case of their absence, displays illustrating the artisans' work are provided.

The Art of the Swordsmiths

Japanese sword making begins first in the forge using tama hagane - clumps of iron which have been wrought from iron sand. The iron from the Chugoku mountains is treated at temperatures of approximately 1,500 degrees Celsius in a smelter to produce the tama hagane.

Mr. Ando is a swordsmith and was raised as the son of a swordsmith. It was from an early age that he was fascinated with the art of traditional sword making. Through the natural course of things he came to follow in his father's footsteps.

The path to becoming a swordsmith is long and rigorous. Swordsmithing requires a national certification to practice, and this entails a number of strict requirements, including an exam. However, to qualify for this exam, the individual must first gain experience in a forge as the apprentice of an already certified sword smith.

The apprenticeship itself must be for at least a period of five years, during which the requisite skills are acquired. The five years of apprenticeship are tested during the exam by a demonstration of forging and tempering skills.

The Process of Making a Japanese Sword

Forging and Tempering Steel

The tama hagane is heated in order to get softened, and is then tempered by hammers wielded here by the apprentices. The swordsmith sets the cadence of the tempering with the tapping of a hammer, as the apprentices raise theirs in turn high above their heads before swinging down with incredible precision.

A tempering demonstration occurs on the second Sunday of every month at the Bizen Osafune Token Village and is open to all visitors. Whether or not you have any appreciation for the art of traditional sword making, even just as an experience, it's unforgettable. The intense heat of the forge and the display of sheer strength and precision wrought through the piercing Clang! Clang! of the hammers, is unlike anything I had ever seen before.

During the tempering process, the steel is folded back upon itself with a cutting tool and the force of a striking hammer. The folded steel is then reheated to soften, hammered, and then folded again. The process is repeated in this manner over a dozen times, creating millions of layers within the body of the metal itself. This also removes the dross from the metal, making it purer and stronger. This technique is, in fact, unique to Japanese sword making and accounts in part for the prestige that it claims in quality.

In forging a blade two different types of steel are used, one harder than the other. The harder steel forms the edge and the tip, while the softer steel is used for the inner and back of the blade, so as to better absorb the shock of a blow. This as well is wrought through the hands of the swordsmith who relies upon both his eyes and ears in determining the appropriate condition of the steel through the entire forging and tempering process.

The forge is only the first step of many in making a sword. On the grounds of the Bizen Osafune Token Village, visitors continue from there to the atelier where the tempered blade is polished and sharpened by another artisan. Here is where the sword is prepared for engraving and for further polishing and sharpening.

The stained wood and large windows under the eaves, upon which kawara (black roof tiles) are set, evoke an atmosphere of an earlier period of Japan. The ateliers and the artisans within each atelier, however, are very much so real and alive as they carry on the tradition of Japanese sword making.

Lacquering the Scabbard

The scabbard that will hold the blade of the sword is fashioned from magnolia wood which itself is let to dry for ten years. Once the scabbard is completed by an artisan, it is then given to another for lacquering and painting. A natural resin is used in lacquering the wood surface of the scabbard. This has the purpose of strengthening and protecting the wood itself. The texture and tone after the final polishing are exquisite and impart a gentle and graceful aesthetic to the scabbard.

Photo courtesy of Takemi Nishi

A base of natural resin is first applied to the surface of the scabbard using washi, Japanese paper. A layer of clear lacquer is applied over the base using a brush made from human hair. The artisan's skills ensure the smooth and even consistency of the ever so fine layers as they are painted onto the scabbard's surface. This is then left to dry for several days. The dried layer is then gently polished using ground charcoal and whetstones, and another layer of lacquer is applied. This process is repeated some dozen times by the artisan over a period of three months.

Fashioning the Blade Collar

Photo courtesy of Takemi Nishi

The habaki (blade collar) is a small piece of metal that has been forged and fashioned into a wedge-shaped article that’s fitted securely into the blade. Often fashioned from copper, the habaki is what holds the sword in its place when sheathed, and prevents it from inadvertently falling out of the scabbard.

It also prevents the blade from contacting the inner surface of the scabbard while sheathed. In essence, it suspends the blade inside of the scabbard regardless of any movement of the sword. The precision of the artisan in creating an exact balance between the blade of the sword and the scabbard is incredibly compelling, leaving as much of an impression as the piercing ring of the hammers in the forge.

Photo courtesy of Takemi Nishi

The hilt of the sword is in turn fashioned by another artisan. At Bizen Osafune Token Village you will be able to meet one with over half a century of experience. The wooden handle of the hilt is first covered by affixing rayskin over its entirety with a glue made with rice. A layer of washi (Japanese paper) is laid over this and provides additional cushioning when gripping the sword. Threads of silk are then wound in a crisscrossing manner down the length of the hilt and form a repeating diamond-shaped design. Implements are used by the artisan in tightly binding the hilt in order to reinforce its strength and provide a firm grip.

This process alone takes weeks to complete and the artisan continues to perfect his work as he experiments and searches out new patterns and methods in binding.

Polishing and Sharpening the Blade

The final polishing and sharpening of the blade are the task of another artisan, the togishi (sharpener and polisher). The final shape of the blade and its curvature are also determined here - first with coarse grinding and then using finer textured whetstones for the final sharpening. The color of the blade is also coaxed out through the polishing. It usually has a whitish tone to the edge and a darker bluish-black tone on the rest.

Photo courtesy of Takemi Nishi

In addition to fashioning new blades, the togishi also works to restore blades previously wrought and have become worn over time. In restoring blades made during an earlier era, the togishi must first research the sword's history, where and how it was made, in addition to checking the blade material itself. This ensures that the original character and integrity of the sword is not lost in the process of restoring it to its original beauty.

Engraving the Blade

Designs are engraved into the sword blade as requested by its eventual owner. During Japan's feudal and medieval periods when the sword was wielded on the battleground, the engravings at the time were far simpler in design in order to lighten the sword's weight. As history turned to peaceful times and the sword was wielded less on the battlefield, the designs became more ornate with auspicious objects such as pine branches, plum blossoms, and dragons.

Photo courtesy of Takemi Nishi

In the engraving stage, the artisan first sketches the design onto paper and then inks it directly onto the surface of the polished blade. By employing a number of chisels varying in size, shape, and hardness, the design is then painstakingly etched into the blade surface.

For every sword commissioned, the swordsmith fashions three blades in the forge. Of these three the finest is selected, polished and sharpened, and is then passed through the hands of other artisans, before it reaches the engraver's atelier. This final stage in the making of a sword is both long and arduous, as the sword retains within it the collective work of the artisans over a period of several months.

Mr. Katayama, the engraver, is currently one of a total of only 15 practicing engravers in all of Japan. It was his interest in the strength and beauty of the katana that first brought him to the art of sword making, and now it's upon him to ensure that his successors carry on the work of engraving.

Walking from one atelier to the next, we happened upon an urn of water holding a pet goldfish, set outside under the eaves. In the window of another atelier we came across a cat snuggled peacefully. Both are pets of the artisans.

It occurred to me then that the Bizen Osafune Token Village is suffused with the spirit of the artisans both in their presence, as well as their absence. Whether it's the tap-tap of the engraver's hammer, the whetstones set neatly in a row in the window, or a pet cat's dish of water in the back of the atelier - one can feel the presence of the artisans at all times.

The Sword Museum - Special Exhibitions and Workshops

Photo courtesy of Bizen Osafune Japanese Sword Museum

The Bizen Osafune Japanese Sword Museum shares the same grounds as the Bizen Osafune Token Village. There is a Training Center here as well, where regular lectures and workshops are held. Through these workshops, visitors can learn and experience for themselves the various aspects of Japanese sword making.

Before you realize it, you'll find yourself completely enraptured by the fascinating and complex art of traditional sword making so expect to spend at least one or two hours at the museum.

Inside the museum you'll find an assortment of displays and objects, as well as multimedia consoles for learning. English language materials and pamphlets are also provided.

A 15-minute video with English captions is one of the invaluable highlights of the museum. The video explains in depth the forging and tampering process, as well as other details that cannot be grasped through observation alone. Although the captions are in English, there are plans to add French and Spanish subtitles as well in the near future.

Replica armors and battle suits are also on display. In addition to taking photographs, visitors are also welcome to try these armors on!

Special exhibitions are also held on the first and second floor of the museum. The exhibitions vary in theme and touch upon varied aspects of Japanese culture both modern and traditional, wherein which the sword is present as an object.

On the day of my visit showcases of swords used primarily as adornment by sumo wrestlers during sacred ceremonies and events were on display.

Find Swords and Other Souvenirs at the Bizen Osafune Museum Shop

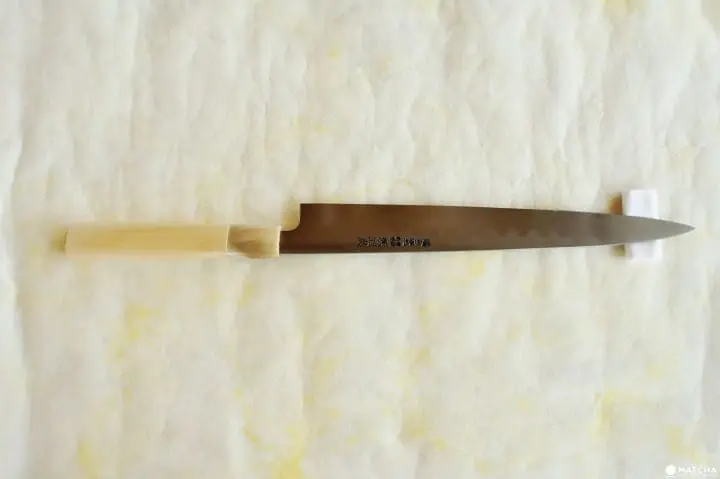

The Bizen Osafune Japanese Sword Museum shop offers a wide array of items that will delight both the casual visitors and the connoisseurs. Swords, knives, paper knives, and a variety of other cutting implements, as well as their respective cases and display holders are showcased on the shelves.

The imitation short swords are especially popular among foreign visitors, who appreciate both their length and the sale price. The longer katana replications won't fit inside most suitcases during the return trip home.

If you would like to acquire your own authentic Japanese sword made by the artisans at Bizen Osafune Token Village, you can order one at the museum.

The beautifully polished blade, and fastened collar, with the silk thread woven hilt and lacquered scabbard reminded me the individual steps carried out by the artisans.

Knives are just as popular with customers as the swords, and an assortment of knives for the kitchen is also on display. I found the the sushi knife particularly graceful, as it was engraved on one side and beautifully designed on the other.

The object on the right is a thread cutter, and is fashioned precisely so as to provide the appropriate level of tension for snipping thread. The nail clipper shown on the left is also a very practical item, popular with the customers.

Paper knives a few centimeters long are fully adorned in scabbards, hilts, and hand guards. This pairing of blades, a katana and wakizashi, is referred to as daisho, and was wielded as such by samurais in battle centuries ago.

The shop keeper himself is a swordsmith and an expert on Japanese swords, and seems to often know what type of souvenir might suit a customer best. Whether it's a full sized sword, a paper knife, or a postcard, the range of items in the shop offers something for all visitors.

Make Your Own Paper Knife!

Visitors are welcome to participate in various workshops, including one focused on finishing and polishing a paper knife. The paper knives are forged in advance, and participants are free to choose one to their liking. The swordsmith, Mr. Ando, explains first the tools and the polishing techniques, and then, over the course of an hour and under his guidance, the participants apply metal to metal in fashioning their own knife.

Voila! In fact, it's more difficult than it may sound, especially when attempting to make the white toned edge of the blade against the dark tone above. The paper knife shown above belongs to another participant, by the way, as mine was in the end far less photogenic.

In Closing

A visit to Bizen Osafune Japanese Sword Museum in Okayama is an incredible experience, unique in all of Japan. The forging demonstration and the artisans at work in the ateliers provide an up close view and an intimate understanding of the art of Japanese sword making. Add to that hands-on workshops and special events, and visitors will quickly realize why Setouchi is considered the capital of Japanese sword making.

This account is managed by MATCHA. We aim to provide useful information to our readers in an enjoyable manner.

![[Okayama] 8 must-visit spots in Yunogo Onsen ~ Spectacular views, nature, museums, lodging ~](https://resources.matcha-jp.com/resize/720x2000/2023/09/01-144768.webp)

![[No need to worry!] A guide to buying entertainment tickets in Japan](https://resources.matcha-jp.com/resize/720x2000/2025/04/21-231654.webp)

![[ Naruto City, Tokushima Prefecture ] Experience the world's largest whirlpools up close on a sightseeing boat at the Spring Whirlpool Festival!](https://resources.matcha-jp.com/resize/720x2000/2025/02/05-222727.webp)